Our machine park includes machines for thread and volumetric erosion. Through erosion, details with a complex shape and great hardness are processed, including hardened details. Inapplicable to processing with these processes are composite and non-conductive materials.

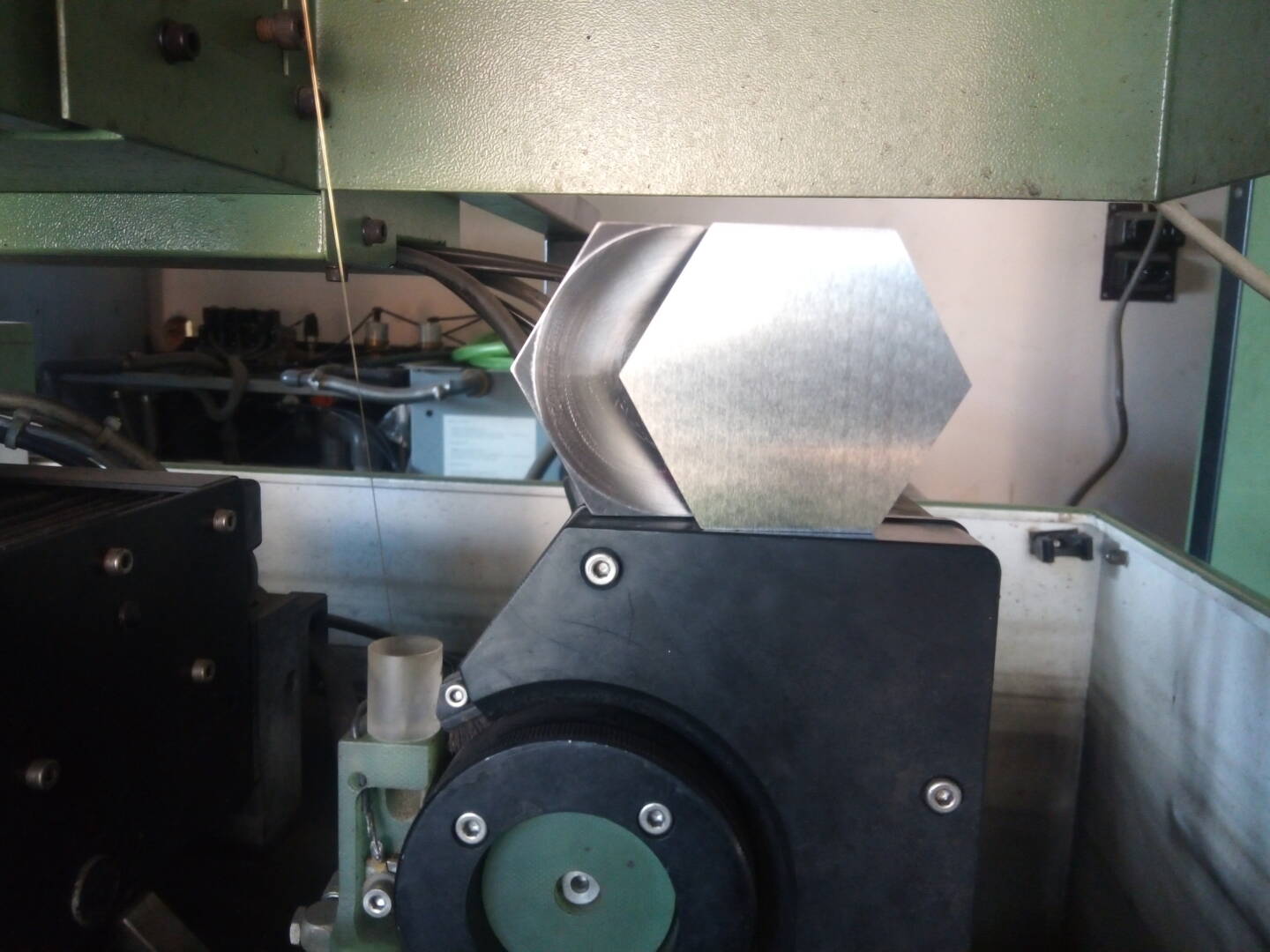

Wire EDM machines can cut parts in various shapes and sizes from almost all types of metal, regardless of their hardness, by means of a very thin metallic molybdenum filament, honey, brass, tungsten, which is usually thick up to 30 micrometer. The details can have a straight or conical shape, as the profile is rectangular or curvilinear. Accuracy is in the order of hundredths of a millimeter.

Filament erosion is used in the production of tooling. Specialized in mold manufacturing, poinsoni, pictures, punches, syringe forms, preforms, dowels, spoke channels etc.

In volume erosion, giving the required shape to the part is usually by copying the shape of a specially made electrode, usually of copper, brass, graphite, etc..

At the point of contact between the spark, produced by the current flowing between the electrode and the workpiece, a depression is formed, the size of which is determined by the specifics of the operating mode. Smoothness can vary over a wide range, which directly affects the timeliness of processing.

A dielectric fluid is used, acting as a conductor, in which the workpiece is immersed. In this processing, the workpiece is formed as a reverse image of the working surface of the electrode.